- Insights

- The Solutionists Hub

- How Does the C-Parts Supply Chain Management Process Work in Practice?

How Does the C-Parts Supply Chain Management Process Work in Practice?

Your supply chain is the journey that the parts and components you use in your manufacturing take to get to you and how they continue moving once you've manufactured your products. On the face of it, it can look like a simple A-to-B journey – but in my experience, many people underestimate the sheer complexity involved.

The supply chain itself is complex enough – but what's really complex is the interconnecting relationships between each stage in the journey and how they affect one another. In this article, I'll try to explain the core stages of the process in more detail and give you insight into how your company should think and act when optimizing your supply chain for maximum efficiency and predictability.

The planning stage

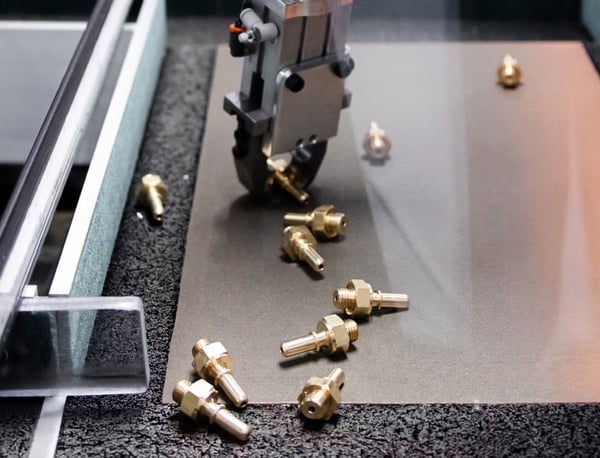

A solid supply chain starts with careful planning. Before you map out how the C-parts get to your production facility, you need to decide what C-parts you actually need.

Even at this stage, you can make decisions that will significantly impact the rest of the supply chain. For example, imagine your R&D department develops a new product that requires a particular type of weld nut. This specific nut could be hard to source, there could be very few suppliers, or it may not be readily available in the specification you require. Already here, you're creating potential supply chain challenges that can affect your operation further down the line.

Sourcing intelligently

Once you've identified your required C-parts, you need to find a supplier that can offer the right quality and quantity and deliver them on time. This sourcing process can be a tough challenge for your business, especially if your products require high tolerances, the supplier has a very high MOQ, or supply chain disruptions slow down delivery. Many companies with a large, unconsolidated supplier base may have several suppliers of the same C-parts to secure their supply. But this creates much higher levels of administration in your company, so you have to find the right balance.

Manufacturing in practice

Once the C-parts are in your company’s hands, you'll notice the knock-on effects of the choices that were made earlier in your supply chain planning. If a particular fastener is harder to handle, assembly on the production line will take longer. More parts (and money) will go to waste if the quality isn't right. If you accept a high MOQ, unneeded parts will clog up your part store, and the wrong choice of supplier could leave you without C-parts when you need them the most.

After production – delivery and returns

Many companies only think as far as the manufacturing stage when thinking about their supply chain. But for your customers, the essential step is the way your products get to them, how they're cared for once they're in their hands, and how they can return them.

Your products continue to have a life long after the point of manufacture. And even if something goes wrong for your customer, the negative situation can quickly be turned into a positive one by a smooth return and repair process. Your C-parts supply chain has a prominent role to play here. Even after a product has gone out of production, you still need to ensure quick access to its components when you require them.

Things to think about

Don't underestimate the supply chain's complexity

In my opinion, too many manufacturers underestimate the complexity of their C-parts supply chains. C-parts are generally the most simple parts you use in your production, so it's easy to assume the supply chain is simple too. But C-parts supply chains are characterized by their complexity, more so than A or B-parts. Your staff often have to juggle large numbers of suppliers, coordinate multiple deliveries, and constantly fight for availability to avoid downtime. By investing time in improving your C-parts supply chain process, you can reduce the burden these seemingly simple parts can have on your entire operation.

Your C-parts supply chain is deeply interlinked

This is why careful planning is so essential when it comes to C-parts supply chains. Your company will feel the impact of choices you make in one stage of the process in subsequent stages. For example, if the durability and performance of C-parts aren’t properly analyzed during sourcing, you may run in to manufacturing problems or reliability issues. Similarly, if a design for a new product requires a less-common C-part, sourcing and replenishment challenges become more likely.

Without these three things, your company will struggle to flourish.

Some companies believe effective supply chain management is just about getting the parts they need at a good price. In reality, it's about taking into account each step of the products' lifecycles and how they interact with different areas of a business, with a goal of ensuring long-term predictability, security and customer satisfaction. Without these three things, your company will struggle to flourish.

Prioritize sustainability

Major manufacturers like you face pressure from customers, employees and shareholders to make serious efforts to improve sustainability. This requires a significant shift in the entire company's thinking, especially in the C-parts supply chain. In the past, engineers and product designers didn't think about mixing materials in manufacturing. It was (and still is) common to inseparably weld different types of metal together. But with recyclability high on the agenda, new construction methods are required. Sustainability will continue to influence the entire C-parts supply chain in the coming years, from planning and sourcing to manufacturing and beyond.

Get a partner

As you can see, the C-parts supply chain management process is a complex one. Creating a process that runs smoothly and effectively requires finding a balance between your company's priorities, goals, and the realities of global trade. Even for large companies with extensive resources, this can be difficult task – so in my opinion, your company would benefit from working with a supply chain partner.

A partner can guide you in all stages of the supply chain, from design to sourcing and beyond. Most importantly, a good partner can ask the right questions and help you find a harmonious balance between each aspect of the supply chain, boosting your company's output and capability.

For more knowledge about C-parts supply chain management, make sure to take a look at our extensive guide on the topic. We also have a free presentation, The Guide to a Seamless Supply Chain of C-Parts, available to download – it'll help you understand the steps a company like yours needs to take to achieve a rational and profitable flow of C-parts throughout your operation.

Get the guide

The Guide to a Seamless Supply Chain of C-Parts

Get new knowledge every week!

Related

-

By Niklas LindsköldHow do EU sanctions against Russia affect your C-parts operation?

-

By Jaroslaw BazeliSupply Chain Strategy Definitions You Should Know

-

By Slawomir BieszkSupply Chain Management Risks, and How to Handle Them

-

By Nick MilesDefining the Objectives of C-Parts Supply Chain Management

-

By Jacob BergströmSupply Chain Challenges and How to Overcome Them

-

By Sergio BrambilaSustainable Supply Chain: How to Reduce Your Carbon Footprint

-

By Jacob BergströmSupplier vs. Supply Chain Partner: What to Choose?