- Insights

- The Solutionists Hub

- Supply Chain Challenges and How to Overcome Them

Supply Chain Challenges and How to Overcome Them

Blog title: Supply Chain Challenges and How to Overcome Them

On a weekly basis, I'm in discussions with our manufacturing customers, preparing them for supply chain challenges. Considering the current importance of the topic, I've decided to formulate my advice in an article. Hopefully, you can use this text as a source of inspiration when planning how to overcome your supply chain challenges.

I have never experienced a situation where the industry faced so many supply chain challenges as in 2020. Although I believe traditional supply chains' risks and structural flaws have long been present, all of a sudden, many circumstances co-occurred, which led to the significant challenges we all face today.

Now is the time to reflect on the lessons learned to build better, more reliable supply chains.

Below, I'll go through the four main challenges manufacturers face with their global supply chain challenges, and at the end, I'll present a solution on how to overcome them.

Demand forecasting

Most companies rely on historical data, either their own or their suppliers, to estimate the future demand for products, solutions, and services. Making supply decisions is becoming more and more difficult as customers' behavior evolves. In 2020, the pandemic outbreak led to a complete change in demand. We saw an apparent increase in demand for some products, while there was a decreased demand for others. In this situation, companies could not rely on historical data because we had never experienced it before.

Port congestion

Due to high shipping demand, lockdowns, and labor disruptions, many ports worldwide already operate at total capacity. Port congestion is when a ship arrives at the port and cannot load or unload because the terminal is already at total capacity. This has been one of the most significant bottlenecks during the pandemic and is still a huge challenge for supply chain management.

Shortage of components

During 2020 we saw many lockdowns and labor disruptions which led to a limited supply of components, affecting all types of supply chains. When the supply of parts and components cannot meet the demand, the imbalance takes a long time to restore.

Rising raw material price

Increased demand for products, port congestion, and shortage of components contribute to increased raw material prices. Meanwhile, costs increase further due to rising prices of surface treatment, packaging material and lack of electricity. Many of the manufacturers I talk with have been severely affected by rising raw material prices.

How to overcome the supply chain challenges

Some situations occur simply by accident, and there is nothing you can do to prevent it. However, if there is one thing I have learned from recent years, unforeseen situations occur, and the companies that are not agile enough will suffer the most.

In my role, I help companies build more flexible supply chains for C-parts, a collective term for the parts which have the lowest value in a product, such as; bolts, nuts, other fasteners, and drawing-controlled details. Traditionally, many companies have used hundreds of suppliers to deliver C-parts, which is very inefficient.

Lately, many have noticed that their supply chain challenges are multiplied by the number of suppliers. If you have a vast number of suppliers for anchors, bolts, hardware, nails, nuts, pins, and clips, each of your suppliers might deal with lockdowns, labor disruption, port congestion, and increased raw material prices. Meanwhile, the administrative work of dealing with multiple suppliers during turbulent times is often overwhelming.

Instead;

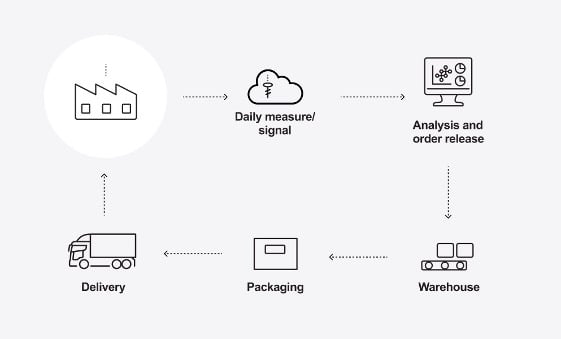

By reducing the number of suppliers and partnering with one supply chain partner, you can get a full-service solution for sourcing, quality control, logistics, and one global contact, with a local presence, language, and expertise.

This is an example of a dual-source solution that mitigates the risk of working with single-source suppliers, as your supply chain partner has a wide network of suppliers. If one supplier fails to deliver, your partner will provide you with another alternative.

Get the Guide to a Seamless Supply Chain of C-Parts

Do you want to know more about implementing a seamless supply chain of C-parts? Then, I can warmly recommend the guide below, explaining what a seamless supply chain of C-parts is, why it's important, and how to achieve it.

Get new knowledge every week!

Related

-

By Niklas LindsköldHow do EU sanctions against Russia affect your C-parts operation?

-

By Jaroslaw BazeliSupply Chain Strategy Definitions You Should Know

-

By Slawomir BieszkSupply Chain Management Risks, and How to Handle Them

-

By Nick MilesDefining the Objectives of C-Parts Supply Chain Management

-

By Rob KoningsHow Does the C-Parts Supply Chain Management Process Work in Practice?

-

By Sergio BrambilaSustainable Supply Chain: How to Reduce Your Carbon Footprint

-

By Jacob BergströmSupplier vs. Supply Chain Partner: What to Choose?