Complexity made easy at lower cost

Bufab Creative Component Solutions™ is a concept based on making complex things easy. We proactively discuss the possibilities with you to achieve an efficient and innovative product. It could be kitted parts in a bag as for IKEA or in a designed packaging where every part has its place, nicely branded. Our local sales companies also have a diverse level of experience to contribute with subassemblies. We are Solutionists and always interested to improve our common business.

What are your kitting needs?

Do you have trouble to make spare parts kits? Did you make spare parts kits and got a shortage in production? Do you have a need to ensure that the exact number of parts were used in a specific production? Do you want your kit of fasteners to enhance your brand? We want to assist you with a solution.

Trouble with assemblies?

We are Solutionists and our aim is to make things easier for you. Does it take too much effort to source all parts for an assembly? Do you lack the space needed for assemblies? Do you have production stops due to missing components? Whatever the reason, we are willing to help to both source and assemble for you.

A solution-oriented way of working

Just like elite gymnasts adapt day-to-day life to perfecting the different elements in their routines based on established objectives, a solution-oriented way of working has become an integrated part of day-to-day operations at Bufab.

Subassemble

By combining your components into assembled parts, we are able to cut direct and indirect costs and reduce the number of suppliers.

With our flexibility and high level of know-how, we offer extensive expertise in parts assembly. We are serving you with a local team backed up by teamwork from our sister companies.

Our local teams have different experience of advanced assemblies and will gather the needed competence for your project. We are Solutionists. Get inspired by the examples below.

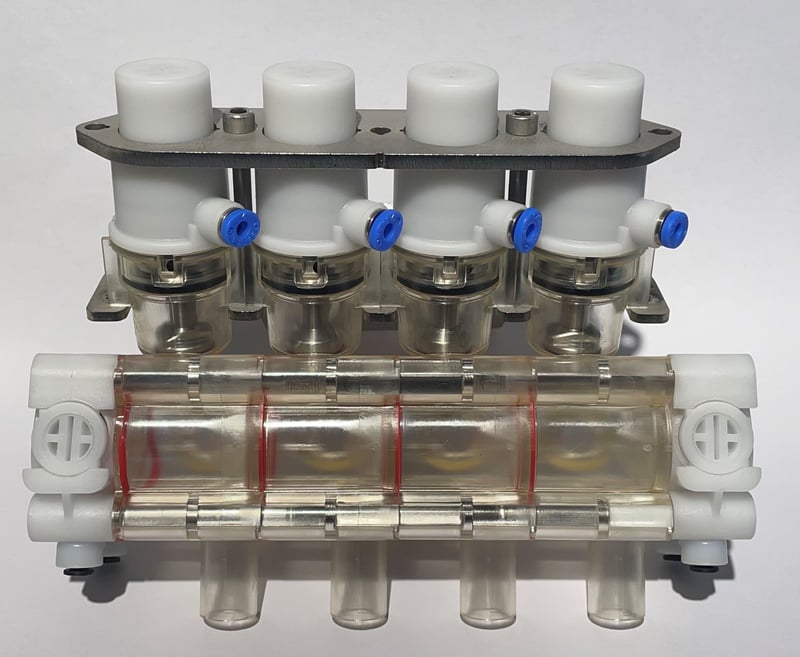

The Valve Block Assembly

The Valve Block Assembly is the core of a milking robot developed by an innovative leader in designing and manufacturing automated systems for dairy farmers around the world, with the goal of excelling in sustainable milk production to feed the world.

The Shower Device

When we met our customer, a large producer of taps, over 10 years ago they felt a lot of frustrations. They spent too much time and energy on one product. The product, a shower device, consisted of many different items sourced from different suppliers and then assembled internally at the customer's production.

Kitting

We offer a wide range of specialized kitting and packing possibilities.

Your parts can be kitted in automated machinery at high efficiency. We can also supply kitted solutions with 100% inspection of the parts according to specifications and with a 100% assured quantity.

Take advantage of the benefits

-

Improved cost control, less waste, fewer stocked items

-

Lower inventory levels

-

Reduced cost of space

-

Increased accuracy: pre-approved parts

-

Greater efficiency, critical parts availability, minimized handling

-

Parts standardization

The benefits of Bufab Creative Component Solutions™

By outsourcing the assembly work, sorting, and packaging of parts, you can achieve the highest level of efficiency more easily.