- Insights

- The Solutionists Hub

- Sustainable Purchasing: Guidance for C-Parts Purchasers

Sustainable Purchasing: Guidance for C-Parts Purchasers

You’ve probably noticed the growing importance of sustainability on the global agenda over the last decade. Environmental, social and economic sustainability is a significant concern for governments and individuals around the world – and industry is facing more pressure than ever before to shift towards more sustainable business models.

If you’re a purchaser at a manufacturing company, it’s likely you’ve also noticed the increasing attention given to sustainability in your organization. Sustainability is beginning to saturate all aspects of manufacturing – from design and logistics to production and aftercare. But as a C-parts purchaser, your department also has a role to play in the transition towards sustainable manufacturing.

During my time at Bufab, I’ve seen the rise of sustainability as a prioritized topic. Increasingly, purchasers ask me how they can make their business practices more sustainable. So in this article, I’ll try to answer by explaining what sustainable purchasing means in practice, provide an insight into current sustainability trends in purchasing and what they mean for you, and give some ideas for how you can increase the contribution the purchasing department makes to your company’s overall sustainability.

What is sustainable purchasing?

Sustainable purchasing is a set of purchasing practices that lets a company get the goods and services they need while having a minimal negative effect or even a positive effect on the environment, society and the economy.

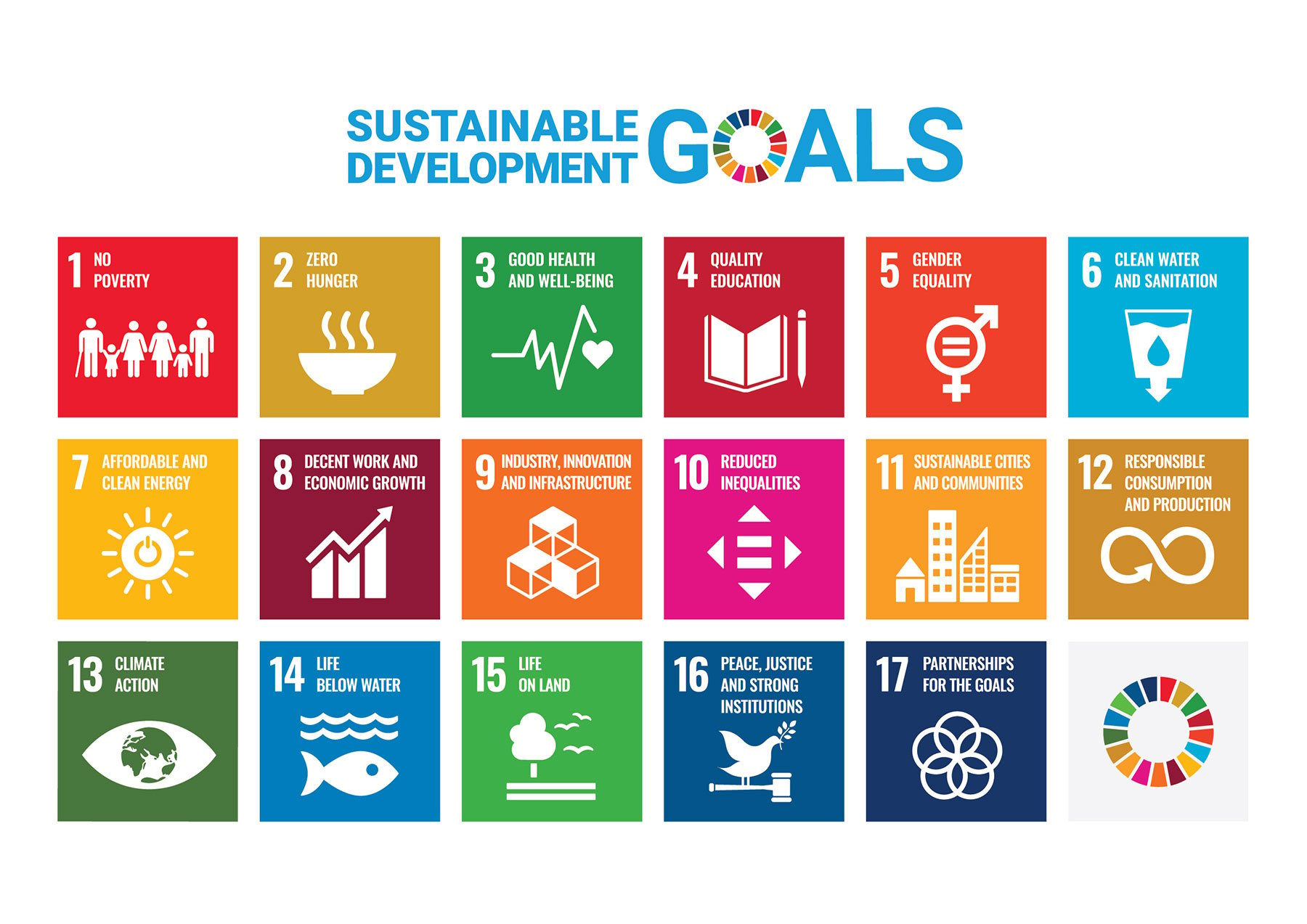

To understand what this means in practice, the 17 sustainable development goals defined in the United Nations Global Compact are an excellent place to start. Over 15,000 companies worldwide have joined the Global Compact and have promised to work towards the advancement of the goals – which include the elimination of poverty, decent work and economic growth, and the preservation of life on land and in the sea.

What does this mean for C-parts purchasers?

On a practical level, the increasing emphasis on sustainability will significantly influence your sourcing and purchasing practices, if it hasn’t already.

In sourcing, sustainability will mainly affect your choice of suppliers. For a company to be truly sustainable, all its suppliers also need to be on the same path – and the C-parts suppliers are no exception. This means that the suppliers must manufacture their products in an environmentally-friendly way – for example, by using renewable energy sources to power their production or by having a well-designed waste management process that prevents harmful substances from damaging the environment. The wellbeing of the suppliers’ staff is also an essential factor – things like child labor or unsafe working environments are not compatible with sustainability. When sourcing C-parts, manufacturing companies should thoroughly vet suppliers before doing business with them – or pass this responsibility on to a partner like Bufab.

When it comes to purchasing, your sustainable ambitions will primarily be defined by how you purchase and deliver your needed C-parts. As we’ve mentioned here on The Solutionists Hub before, many manufacturers struggle with a large, unconsolidated supplier base for their C-parts, where small quantities of components are purchased from a large number of suppliers. Aside from being problematic for the business, it can also be an unsustainable approach – many suppliers mean many deliveries, and if the suppliers are far away from your manufacturing facility, this can result in high levels of emissions.

By consolidating the supplier base and ordering more C-parts from fewer suppliers, deliveries can also be consolidated – creating greater levels of efficiency and reducing the number of resources that need to be consumed for you to get the C-parts you need.

Sustainable trends to consider

Circularity

Circularity aims to extend the life of raw materials used in products dramatically. It’s still common for products to be discarded and consigned to landfill at the end of their life. When this occurs, the materials used to manufacture them are permanently lost. In a circular approach, the materials from this discarded product – for example, metals or plastics – can be repurposed as raw materials when producing an entirely new product. For manufacturers, this may mean changing the kinds of C-parts that are purchased, or sourcing suppliers who have committed to circularity and have implemented it in their production processes.

Recyclability

If a product can’t be reused or possibly remanufactured at the end of its life, the best option for sustainable disposal is typically recycling. However, many products are hard to recycle, often because of the materials used or the inseparability of components made from different materials.

Purchasing choices can play a big role in a company’s sustainability performance. For example, when purchasing plastic C-parts, the company could choose more recyclable types of plastic. Decisions about which materials to use are often the responsibility of R&D, but this example shows how purchasing decisions can make a real impact on the company’s overall sustainability efforts.

Recycled materials

It’s common in the world of consumer goods to see brands prominently advertising the recycled materials used in their products, and I’ve noticed this trend arriving in the industrial manufacturing space as well. For example, by designing products that use C-parts made from recycled plastic or metal, a company can significantly raise their sustainable profile.

How to make your purchasing more sustainable

Audit and consolidate your supplier base

As my colleague Slawomir has written about before, placing the responsibility for C-parts in the hands of a few suppliers (or only one) has numerous financial and organizational benefits for almost all manufacturing companies. However, it can also boost the sustainability of your C-parts supply chain. Fewer suppliers mean fewer C-parts shipments, and with a supply chain partner that can consolidate deliveries, you can reduce the number of transports required during the final stage of your C-parts’ journey to your production facility.

Set sustainability goals

Setting goals and deciding which factors to measure helps you track your progress towards sustainable purchasing and gives you something to aim for. You can consider numerous goals – for example, the reduction in your number of suppliers through consolidation, or the carbon emissions generated by your entire C-parts supply chain. Your supply chain partner will be able to help you analyze your current situation and provide you with the figures you need.

Get a partner

Auditing the entire C-parts supplier base for sustainability and analyzing the environmental impact of the supply chain can be an overwhelming task. If you have high ambitions, it’s generally better to get help from a supply chain partner. They’ll likely have better oversight of suppliers than your company, which allows them only to choose firms that meet your requirements for environmental impact and social responsibility.

Their additional expertise will allow them to optimize your C-parts portfolio. Through analysis and careful planning, a good partner can find a way to get you all the C-parts you need while also ensuring you get a low environmental impact and sustainability-conscious suppliers.

Hopefully, this article answers your questions about the relationship between purchasing and sustainability and gives you some ideas of the impact you can have on your company’s overall sustainability practices. For more knowledge about C-parts purchasing, make sure to take a look at our extensive guide on the topic – and don’t forget to download The C-Parts Purchaser’s Guide to Supplier Consolidation below, to understand how to get started with reducing your number of suppliers.

Get new knowledge every week!

Related

-

By Jonas CaseliusHow Does the C-Parts Supplier Consolidation Process Work in Practice?

-

By Maria GötessonCommon C-Parts Purchasing KPIs, and How to Improve Them

-

By Oskar SvenssonVendor Managed Inventory: The Benefits of VMI for C-Parts Purchasers

-

By Jacob BergströmWhat is the Total Cost of Ownership in C-Parts Purchasing?

-

By Tuomo TiainenMy Tips for How to Succeed as a C-Parts Purchaser

-

By Slawomir BieszkHow to Source C-Parts: Tips for Purchasers

-

By Slawomir BieszkMOQ: How to Deal With High Minimum Order Quantity for C-Parts