- Insights

- The Solutionists Hub

- My Tips for How to Succeed as a C-Parts Purchaser

My Tips for How to Succeed as a C-Parts Purchaser

I know from personal experience that as a C-parts purchaser, you’re under pressure from all directions – not only from your own department, but from production and management as well. C-parts are vital but often unappreciated, and even if you’re consistently making the right parts available at the right time and in the right quantity, your good work can go unnoticed. It’s only when availability falls that attention turns to you, and the purchasing department gets the blame for being a bottleneck in the vital manufacturing process.

If you’re responsible for the day-to-day work of purchasing C-parts for your company, it can be hard to gain appreciation – so in this article, I’ll try to explain the core challenges that you’re facing in your role, the core KPIs that you should be focusing on if you want to succeed, and most importantly, how to improve them.

The challenges you’re facing

Bufab has written about the benefits of supplier consolidation before on The Solutionists Hub. Like they explain, if you’re dealing with 20 or 30 C-parts suppliers, each with its own contact person, ordering process and logistics practices, you’re going to have a lot of repeated work. It’s simply not efficient to deal with all this administration when you can consolidate your suppliers and get all your needed C-parts from a few partners, or maybe even just one.

The consequences of an unconsolidated pool of suppliers can be significant, so this is a major challenge for purchasers and sourcers at manufacturing companies. But if your company already has a fairly consolidated supplier base, it’s likely that these aren’t the challenges you’re dealing with.

Instead, your challenges may have more to do with the level of service you’re getting from your supplier. Your supplier needs to have a solid understanding of your business and the needs and challenges of your production, not only now but in the future as well. Without an informed partner, you may struggle to adapt and develop your C-parts operations as your company’s needs change. Similarly, the service you receive might depend on your business’s definition of C-parts – is it just fasteners, or other types of supplies? Can you get everything you need from the supplier’s catalog, or do you require custom-made components? Naturally, your partner needs to be able to handle your demands if your purchasing processes are going to run smoothly.

As a purchaser, your focus is often on the actual products you’re purchasing – but when it comes to C-parts, the products are actually the easier part. The real challenges arise in your interactions and cooperation with your C-parts supplier. If they're just solving everyday problems and not proactively working to prevent them in future, your performance will suffer – and in serious cases, this could lead to other challenges, like low C-parts availability.

The KPIs you’re up against

The challenges described above are the ones that you’ll need to handle in your role – but apart from these, there’s probably a number of key performance indicators that you’re measured on. Your KPIs may vary depending on your business, but these two are almost always the most important for C-parts purchasers:

Availability

Regardless of how well you’re taking care of your daily work, if any C-parts aren’t available in production when they’re needed, then you’ve failed. If parts aren’t available, downtime occurs – and every minute your production process is out of action carries a huge cost.

Factors like price and quality have a role to play when you’re purchasing C-parts – but the most important thing is that the parts are actually available.

Lead time management

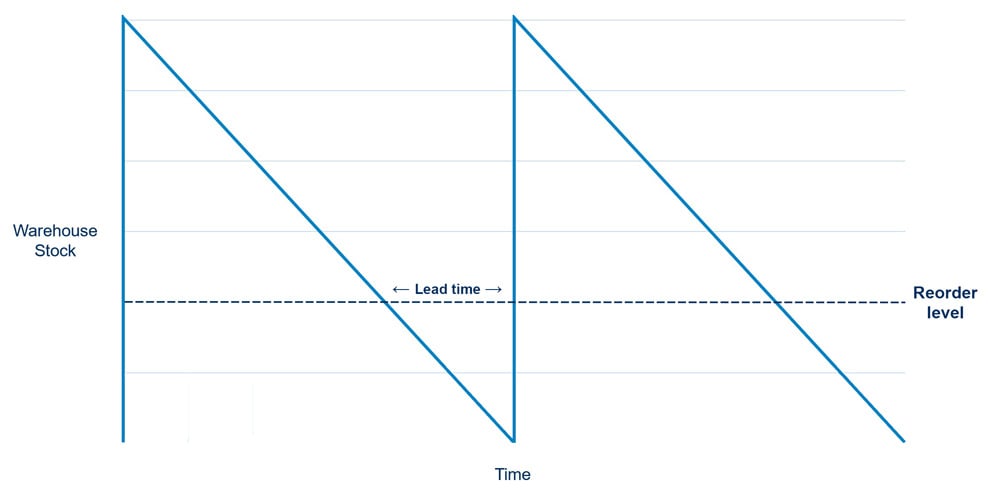

The way you handle lead times, and manage time in general, is closely linked to the issue of availability. Your company’s production line may require hundreds of different C-parts to manufacture your products, and each of these parts may have different lead times from your supplier. In the same way, demand for certain parts may fluctuate depending on the kinds of products being manufactured.

To make sure that you keep your C-parts availability high, you need to have a detailed overview of the demands of your production (now and in the future) and the limitations of your suppliers. Failure to coordinate the lead times of your C-parts and your company’s needs can lead to major issues.

How to boost your performance

So, with all these challenges and KPIs in mind, the question is – how do you actually boost your performance and become a successful C-parts purchaser?

In my position, one of the most important things I’d like to see in a purchaser is that they have a day-to-day overview of what’s happening in the company and with our suppliers. They need to be able to react quickly and get the timing right when requirements change in the production, and this can only happen when a purchaser has control over their work and knows what’s happening.

If a purchaser has these qualities, I know that the daily purchasing work is going to go smoothly without too many difficulties. But on top of that, a purchaser like this can actually create new opportunities for the company – if production knows that their sourcing and purchasing department is dynamic and flexible enough to solve tough challenges at short notice, they can work more effectively and innovatively than before. In this way, the purchasing department can actually drive progress, and not just create bottlenecks.

The importance of proactive relationships

Having this level of control requires the purchaser to have a good relationship with their supplier. Relationships like these allow the supplier to really understand the company’s needs better, which in turn allows them to be proactive and come up with improvements and changes ahead of time, at their own initiative - rather than just taking things day-by-day.

Succeeding as a purchaser

As I’ve already mentioned, C-parts purchasing can be a challenging and unrecognised field. But if you know the things you’re actually being measured on and have a plan to improve them, you’ll be able to succeed in your position.

Bufab has some more resources that can help you optimize your C-parts purchasing. For example, The Purchaser’s Guide to C-Parts. They also have a downloadable guide, The Purchaser’s Guide to Supplier Consolidation, which is available below. It goes into more detail about the most important benefits of consolidation, and gives you a practical example of how a typical supplier consolidation process can work.

Get new knowledge every week!

Related

-

By Jonas CaseliusHow Does the C-Parts Supplier Consolidation Process Work in Practice?

-

By Maria GötessonCommon C-Parts Purchasing KPIs, and How to Improve Them

-

By Oskar SvenssonVendor Managed Inventory: The Benefits of VMI for C-Parts Purchasers

-

By Jacob BergströmWhat is the Total Cost of Ownership in C-Parts Purchasing?

-

By Carina LööfSustainable Purchasing: Guidance for C-Parts Purchasers

-

By Slawomir BieszkHow to Source C-Parts: Tips for Purchasers

-

By Slawomir BieszkMOQ: How to Deal With High Minimum Order Quantity for C-Parts